Edit PDF online with our all-in-one PDF editor

Users trust to manage documents on pdfFiller platform

Instructions and Help about edit pdf online

With pdfFiller, you can easily edit PDF files and make any changes you need.

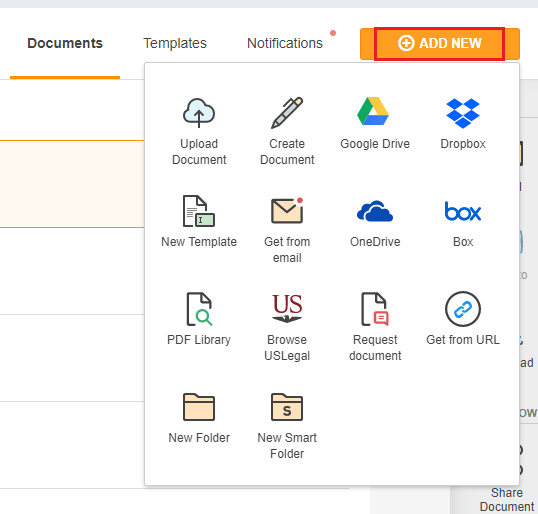

Upload, import or open the PDF you need to edit. pdfFiller supports PDF, Word, PowerPoint, JPEG, PNG or Text formats.

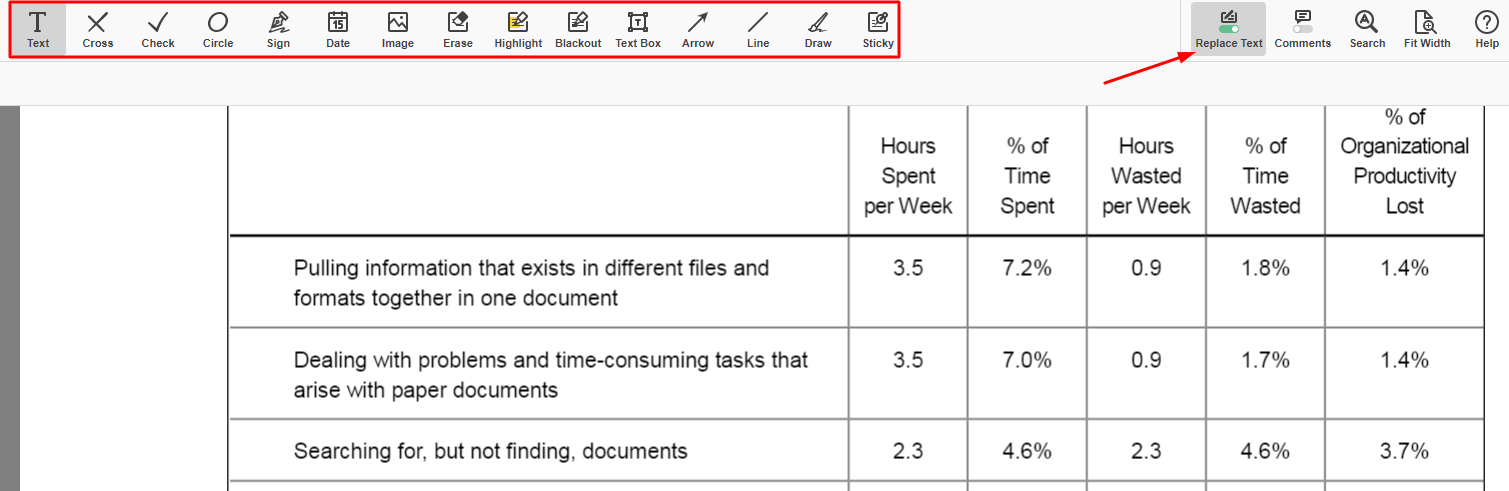

Change the existing text or type anywhere in the document. Add text boxes, erase, highlight or blackout parts of the original document.

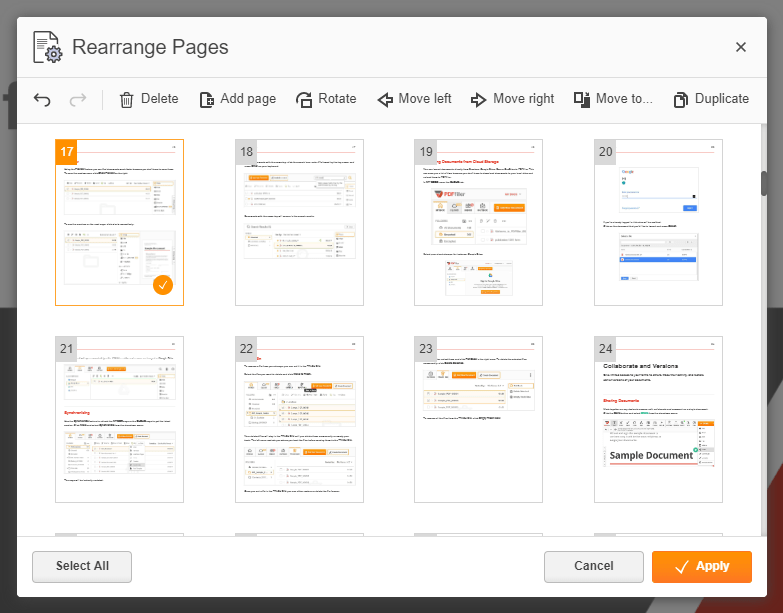

Rearrange the page order of your document, add, duplicate or delete pages.

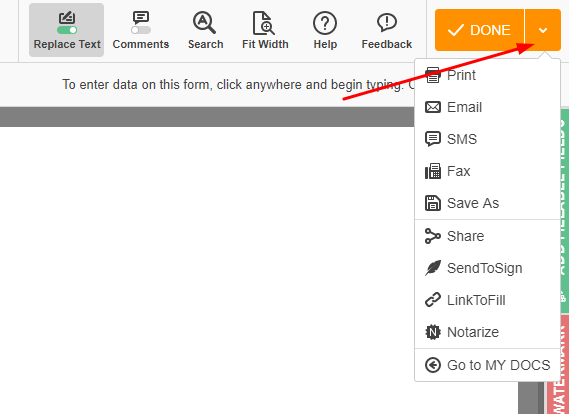

Save the changes made with the online PDF editor and print or download the file. You can also share the document with your business partners for them to edit or fill it out.

How to edit a PDF online with pdfFiller:

How to Use the Edit PDF Feature in pdfFiller

The Edit PDF feature in pdfFiller allows you to easily make changes to your PDF documents. Follow these simple steps to use this feature:

Using the Edit PDF feature in pdfFiller is quick and easy. Start editing your PDF documents today and experience the convenience of pdfFiller!

What our customers say about pdfFiller